Estimated reading time: 4 minutes

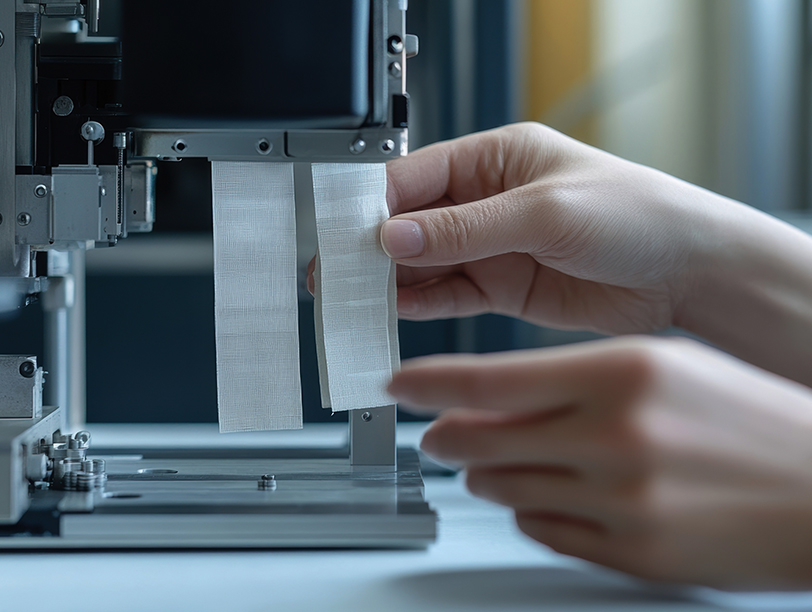

In medical device development, a product is only as strong as the data behind it. Tensile testing—one of the most widely used mechanical tests—gives engineers and manufacturers the material intelligence they need to move from design to production with confidence. At Medical Extrusion Technologies (MET), tensile testing isn’t just a lab procedure—it’s a development tool integrated early into the extrusion process.

Let’s explore what makes tensile testing essential, how ASTM-compliant methods are applied, and how our in-house capabilities give manufacturers an edge.

View our Tensile Testing capabilities for medical tubing and thermoplastics

The Role of Tensile Testing in Device Development

Tensile testing reveals how materials behave when stretched, helping teams measure strength, elasticity, and durability. For tubing, sheaths, catheters, and multi-lumen profiles, it can validate polymer selection, extrusion integrity, and performance under load.

Rather than treating tensile testing as a final QC step, engineers increasingly rely on this data at the earliest stages of design. That’s where Medical Extrusion Technologies provides a distinct advantage. “Medical Extrusion Technologies can provide tensile testing information early in the development process as an initial data point, or on an ongoing basis,” says Brian Frechette, Operational Strategist at MET.

“The advantage of tensile testing early in the customer product development process can streamline the process, leading to quicker development and potentially reduced long-term costs.”

This approach not only accelerates timelines, but also supports product designs that remain compliant with regulatory expectations—without inflating production costs.

ASTM Standards That Guide Medical Tensile Testing

Tensile testing in the medical device space must meet strict regulatory and material-specific benchmarks. At MET, all testing is ASTM-compliant, using standards tailored to specific material types and applications:

| Standard | Material Type | Common Applications |

| ASTM D638 | General plastics | Catheters, sheaths |

| ASTM D882 | Thin films | Coatings, flexible pouches |

| ASTM D412 | Elastomers | Gaskets, seals |

| ASTM F88 | Seals | Sterile packaging |

| ASTM F2027 | Bone plates | Orthopedic devices |

Tensile strength testing data is one of the most commonly cited mechanical performance metrics in FDA 510(k) premarket notifications for polymer-based medical devices. By adhering to these benchmarks, MET ensures repeatable results that can support FDA and EU MDR submissions.

What Data Does Tensile Testing Provide?

Tensile tests generate a stress-strain curve, from which several key metrics are derived:

- Tensile Strength – How much force a material can withstand before breaking

- Yield Strength – The point where a material starts to bend or stretch and won’t return to its original shape

- Elongation at Break – How far a material can stretch before it snaps

- Modulus of Elasticity – How hard it is to stretch or compress a material

- Poisson’s Ratio – How much a material gets thinner when you stretch it

- Reduction in Area – How much the material’s thickness shrinks right before it breaks

Different materials behave differently under tensile load: ductile materials stretch and absorb energy, while brittle ones may fracture without warning. This is why tensile testing is often the first step in selecting and qualifying extrusion materials for critical components. This data helps product teams compare materials, validate design tolerances, and ensure the final device behaves predictably under real-world forces.

Types of Tensile Testing for Medical Applications

While the basic test involves stretching a sample until it breaks, variants of tensile testing are often used depending on the material and application:

- Standard Uniaxial Testing – Most common, using constant pull until failure

- Cyclic Testing – For fatigue performance and repeated use scenarios

These test variants offer insight beyond static strength, revealing how devices perform over time and under stress.

Common Failure Modes—and How to Prevent Them

Tensile testing doesn’t just tell you when a product fails—it helps you understand why. As highlighted in a 2023 study, understanding and predicting the mechanical behavior of polymers is vital for the successful development of medical devices.

There are a couple ways product failures come about…

According to Frechette, the most common failure modes observed are “mechanical failure, environmental degradation, manufacturing defects, and design inadequacy.”

Each of these failures points to a different underlying issue, whether it’s weak material bonding, degradation from sterilization, poor extrusion technique, or underengineered cross sections.

The best mitigation strategy?

“Working directly with the customer to understand product performance requirements early in the process is the best way to avoid future issues with tensile performance.” – Brian Frechette

This collaborative approach allows MET to optimize polymer selection, processing conditions, and dimensional tolerances—all before a prototype hits the test stand.

Why In-House Testing Saves Time (and Cost)

With tensile testing available in-house, MET shortens the feedback loop between extrusion and mechanical evaluation. That means:

- Fewer delays waiting on third-party labs

- Quicker material comparisons during prototyping

- Early detection of design or manufacturing issues

- Seamless integration with other in-house services, such as annealing or multi-lumen coextrusion

Whether you’re testing Pebax, PEEK, polyurethane, or complex multi-lumen configurations, fast, repeatable tensile data can shape decisions at every phase of development.

Working with the Right Tensile Testing Partner

Mechanical performance data shouldn’t be an afterthought. At Medical Extrusion Technologies, tensile testing is built into the product development process—whether you need early material evaluation, long-term performance comparisons, or consistent QC benchmarks.

With ASTM-compliant equipment, custom fixture development, and specialized testing of medical-grade thermoplastics, we support engineers and manufacturers in delivering products that perform reliably—when it matters most.

Comments are closed