What is Tensile Testing?

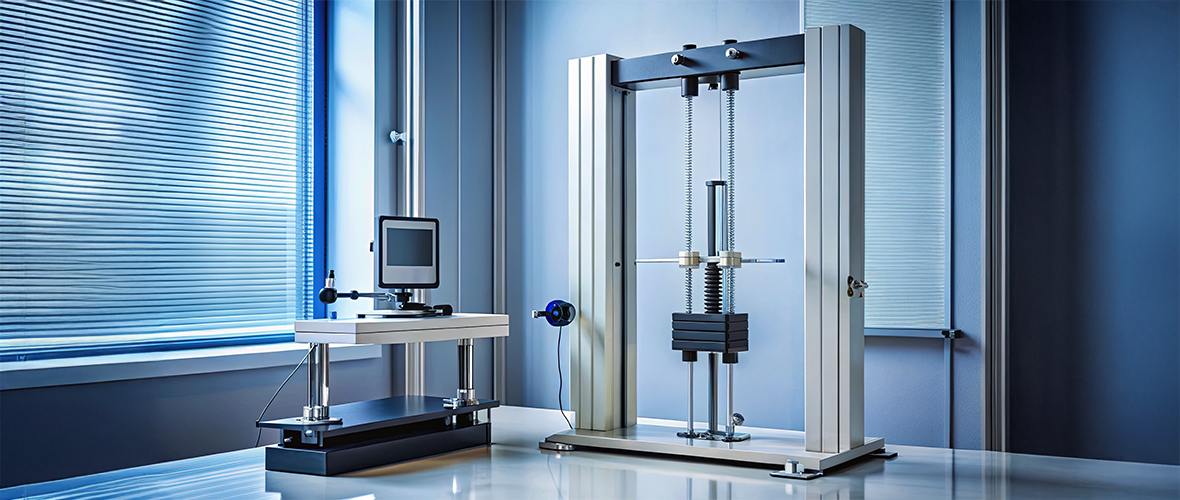

Tensile testing is a standardized mechanical testing method used to evaluate how a material or component responds to uniaxial tension—how it stretches, deforms, and ultimately breaks under load. This process provides essential data on properties such as tensile strength, elongation, modulus of elasticity, and yield point. For medical device applications, tensile testing is crucial for validating the mechanical performance of polymer materials and extrusion profiles before clinical use.

At Medical Extrusion Technologies (MET), tensile testing is performed in-house as part of our integrated quality and product development process. Whether testing raw materials, tubing, monofilament, or multi-lumen extrusions, our ASTM-compliant methods provide the confidence needed for medical-grade performance.

Custom Tensile Testing Solutions

MET’s in-house tensile testing capabilities are designed specifically for the demands of the medical manufacturing industry. We perform tensile testing on a wide range of thermoplastic materials and extrusion profiles, including:

- Tubing (coextruded, single-, and multi-lumen)

- Monofilament and braided elements

- Flat test samples

- Specialty profiles

All tests are conducted using ASTM-compliant protocols, with precise control of grip geometry, strain rates, and environmental conditions to ensure accurate, repeatable results.

Applications of Tensile Testing in Medical Manufacturing

Tensile testing plays a critical role in medical device development, enabling engineers and project teams to:

- Validate raw material properties for regulatory compliance

- Optimize mechanical performance for catheters, sheaths, and delivery systems

- Simulate in vivo tensile loads and failure modes

- Support design-for-manufacturability with accurate stress-strain data

- Document and verify performance for FDA or CE submissions

Common use cases include evaluating yield strength in catheter shafts, elongation in microbore tubing, or tensile limits in extruded components used in minimally invasive procedures.

Why Choose Medical Extrusion Technologies?

At Medical Extrusion Technologies, we integrate tensile testing into every phase of your extrusion project. Our in-house lab capabilities mean faster turnaround, tighter quality control, and data-driven development—all without relying on third-party test labs. By combining deep materials expertise with ASTM-compliant testing, we help our partners reduce risk, accelerate timelines, and build better medical devices. Choose MET for tensile testing that supports your innovation, from polymer selection to performance validation.

Contact us today to learn more about our in-house testing services and extrusion capabilities.